Project Description

Special requirements:

- Processing of high-end, filled and glass fibre reinforced resins

- Wear resistant systems

- Multi-component applications

- Processing of Liquid Silicone Rubber (LSR)

- Reel-to-reel overmoulding with short distances between cavities

EWIKON solutions:

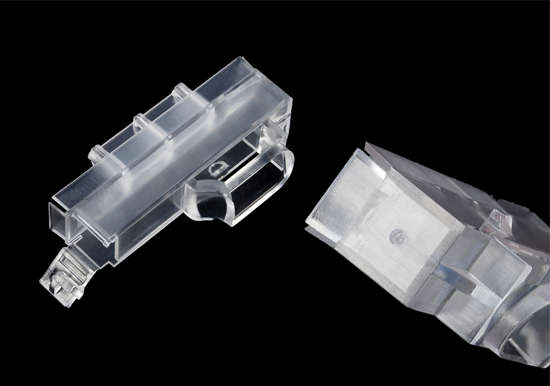

Connector plug

| Material: | PA 6.6 with 30% glass fibre |

| Part weight: | 3.5 g |

| Mould: | Hot runner mould integrated in fully automated production line |

| Hot runner system: | Direct side gating. Radial nozzle |

| Cavities: | 12 |

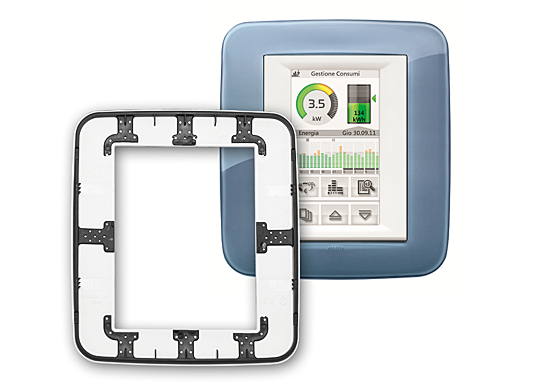

Cover plate for home automation system

| Material: | PC (coloured surface) ABS (white back layer) ABS (black support frame) |

| Part weight: | 60.5 g |

| Mould: | 3-component rotational mould |

| Hot runner system: | Coloured surface and back layer: valve gating with electric drive units Support frame: open gating with single tip on auxiliary sprue |

| Cavities: | 1+1+1 |

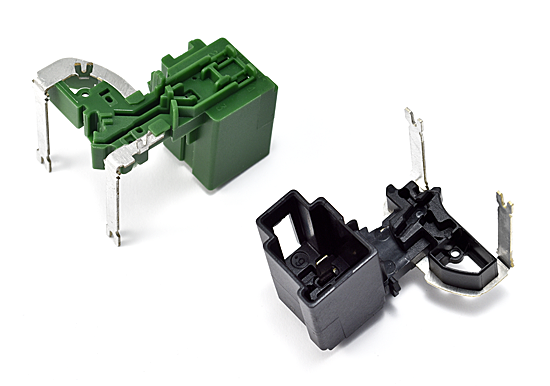

Motor contact plug

| Material: | PBT ULTRADUR with 30% glass fibre |

| Part weight: | 2 g |

| Mould: | Fully automated production cell with integrated injection moulding machine |

| Hot runner system: | Slim nozzles in linear arrangement with small distances between cavities |

| Cavities: | 12 |

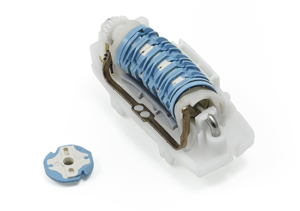

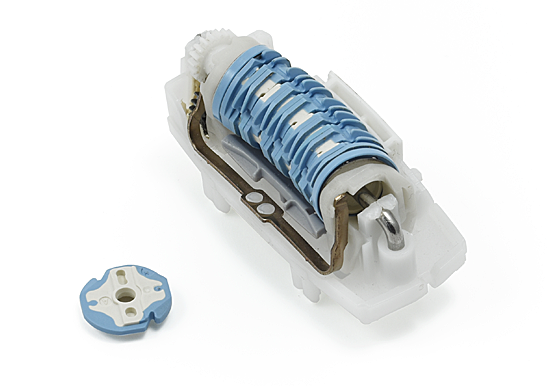

2-component tweezer discs for epilating head

| Material: | PA with teflon additive (body), PA with ceramic and glass fibre (tweezer blade) |

| Part weight: | 0.18 g (body), 0.1 g (tweezer blade) |

| Mould: | 2-component rotational mould with full and partial hot runner system |

| Hot runner system: | Slim nozzles for direct gating (body). Partial hotrunner with gating on subrunner (tweezer blade) |

| Cavities: | 24 |

Air by-pass valve housing for vacuum cleaner

| Air by-pass valve housing | Flap for air by-pass valve | |

| Material: | ABS | ABS |

| Hot runner system: | Direct side gating. Linear nozzles. | Direct side gating. Linear nozzles. |

| Cavities: | 8 | 16 |

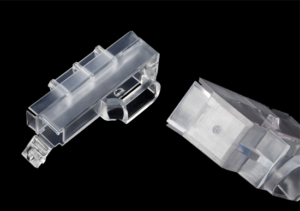

Filter change indicator housing for vacuum cleaner

| Material: | PCTA |

| Hot runner system: | Direct side gating. Radial nozzles |

| Cavities: | 4 |