Project Description

Special requirements:

- High quality injection point and surface for visible parts

- Materials with a high filler content

- IMD decoration

- Cascade moulding

- Complex part geometries

EWIKON solutions:

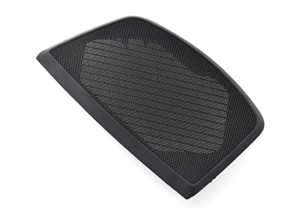

Pull-out panel

| Material: | PP TV20 |

| Mass of moulding: | approx. 1000 g |

| Form: | Injection through the ejector unit |

| Hot-channel system: | 7 injection points per moulding, long nozzles |

| Sockets: | 1+1 |

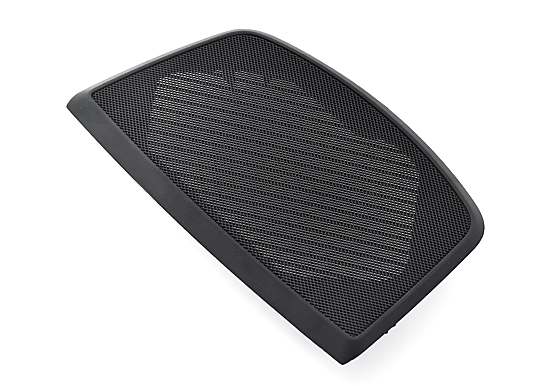

Loudspeaker grille

| Material: | PC-ABS, Bayblend T65XF |

| Mass of moulding: | 45 g |

| Form: | Injection through the ejector unit |

| Hot-channel system: | 7 injection points per moulded part, contour directly in the insert |

| Sockets: | 1 |

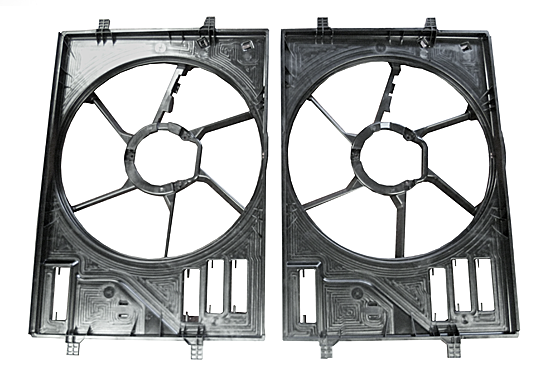

Housing

| Material: | PA66 GF30-Mucell |

| Mass of moulding: | 900 g |

| Hot-channel system: | 5 injection points per moulded part, contour directly in the insert |

| Sockets: | 2 |