Project Description

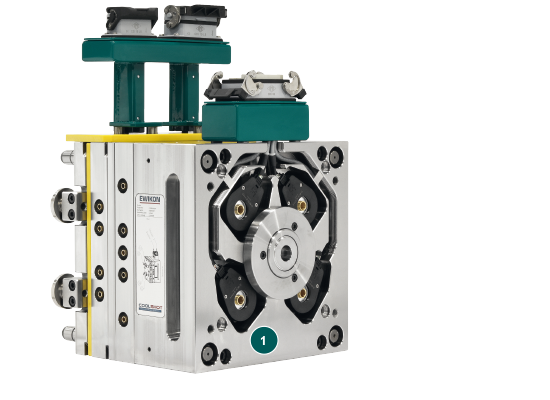

The EWIKON COOLSHOT cold-channel system ensures reliable processing of all types of liquid silicone rubbers (LSR). The innovative proven technology guarantees perfect filling of the sockets, homogeneous cross-linking due to even heating and reduced cycle times. The system is supplied complete and ready for installation of the cold half.

More information:

A new benchmark for LSR processing

- Filler technology with electric linear stepper motors

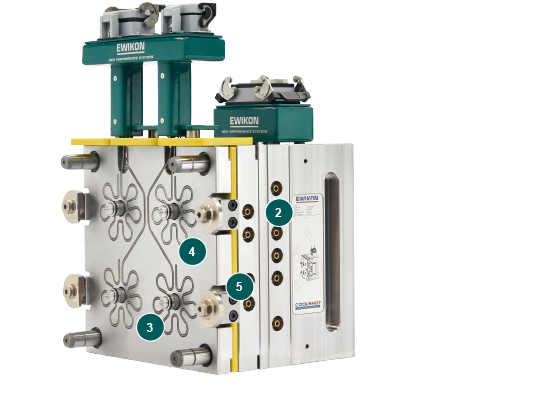

Leading technology from the hot runner systems sector. Precise positioning of the valve needle. Minimised system start-up and readjustment time during production. - Easy-to-maintain balanced manifold technology

The balanced flow channels and streamlined flow channel layout allow for quick colour changes. The manifold assembly can be easily disassembled and opened for cleaning. - Optimised cycle times and ideal injection points thanks to advanced nozzle technology

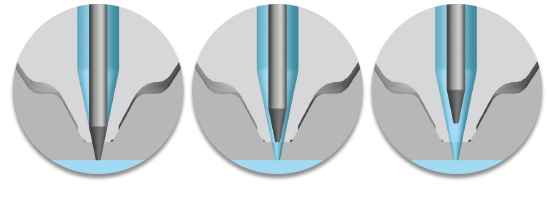

Excellent thermal separation achieved by using different tip designs for water-cooled cold channel nozzles. This ensures optimised cycle times for different LSR types. - OPTION: Homogeneous socket plate heating

Heated separator plate with efficient spiral heaters and separate temperature control for each slot. Significantly more even heat profile compared to cartridge heaters. - OPTION: Quick release device for removing the socket plate

Once production is complete or in the event of a temporary interruption, it is possible to quickly separate the hot cavity plate from the cold channel nozzles. The cold-channel system is protected against LSR cross-linking.

Perfectly precise balancing of cavity filling

The tapered valve needles, combined with the high-performance electrically driven gate valve technology, enable precise control of the filling of each seat and a reliable hose seal.