Project Description

Special requirements:

- Excellent gating point and surface quality

- Short cycle times

- High repeatability

- Multi-cavity systems

- Clean room compatibilty

- Side gating of parts

- Compact moulds

EWIKON solutions:

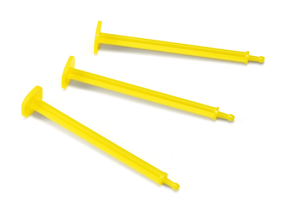

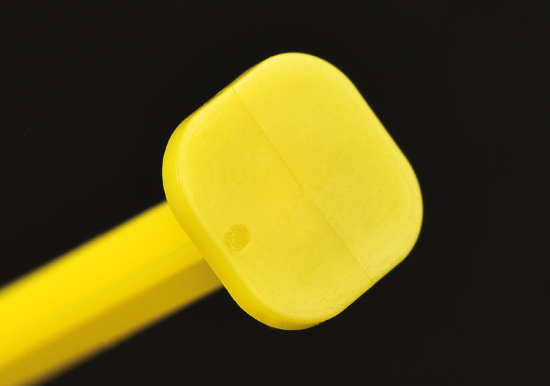

Plunger for three-piece disposable syringes

| Material: | PP |

| Part weight: | 0.35 g |

| Mould: | Stack mould |

| Hot runner system: | Direct side gating. Linear nozzles, 8 tips |

| Cavities: | 48 + 48 |

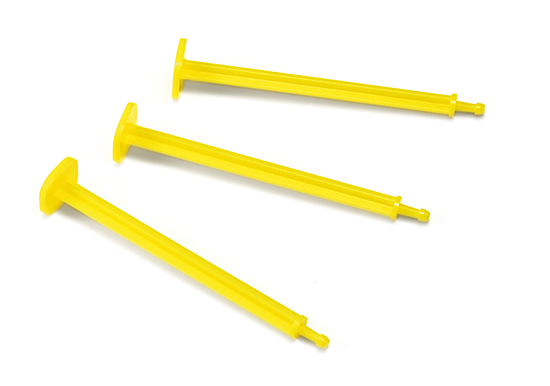

Two-piece disposable syringes

| Material: | PE (plungers) PP (barrels) |

| Mould: | 10 moulds for barrels and plungers |

| Hot runner system: | Direct side gating. Linear nozzles for plungers, radial nozzles for barrels. |

| Cavities: | 48, 32, 24 and 16 (depending on the size of the syringe) |

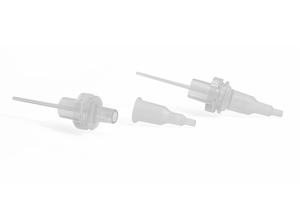

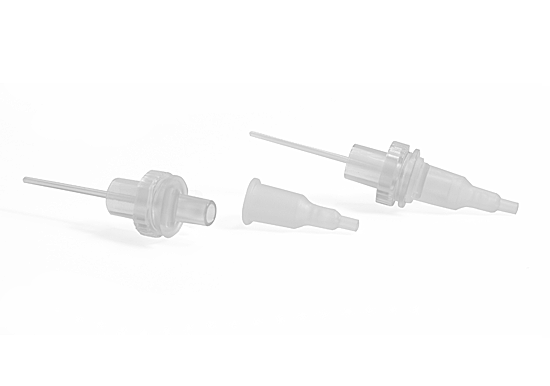

Clot trap with venting adapter

| Clot trap | Venting adapter | |

| Material: | TPU | SAN |

| Part weight: | 0.17 g | 0.45 g |

| Hot runner system: | Direct side gating. Radial nozzles | Synchronous plate valve gate system |

| Cavities: | 48 | 16 |

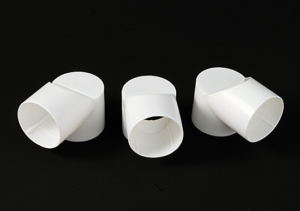

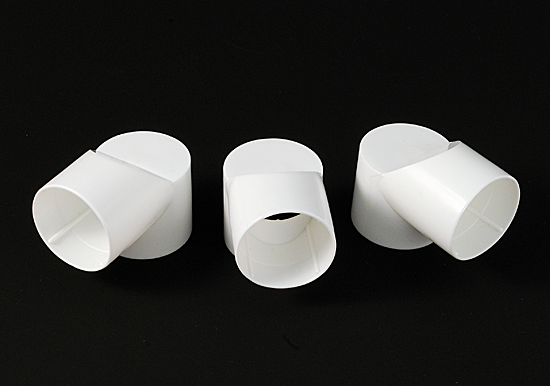

Head for asthma spray

| Material: | HDPE |

| Part weight: | 3.5 g |

| Hot runner system: | Direct side gating. Linear nozzles |

| Cavities: | 16 |

Syringe barrel for dental industry

| Material: | Topas (COC) |

| Hot runner system: | Direct side gating. Linear nozzles |

| Cavities: | 16 |