Project Description

Tungsten copper also known as 'ALTRONITE, CuW, WCu' - is an alloy with a min. 70% tungsten (W) content (which is why some people call it 'tungsten copper').

Tungsten copper also known as 'ALTRONITE, CuW, WCu' - is an alloy with a min. 70% tungsten (W) content (which is why some people call it 'tungsten copper').

The addition of tungsten has a significant effect on the specific gravity of the alloy, in which the high electrical and thermal conductivity of copper has been combined with the high wear resistance of tungsten, making the alloy ideal for electrical discharge processes.

An additional advantage of alloy over copper is that with long and thin electrodes there is no deformation.

Main alloy applications:

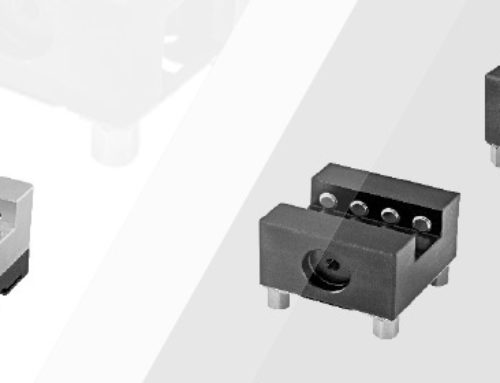

- EDM electrodes

- electrodes for resistance welding

- contactors

Copper tungsten is available as finished thread electrodes, tubular electrodes, flat bars, round bars and square bars.

| Composition | Density | Hardness | Resistivity | IACS | Bending strength |

| (Tuesday %) | (g/cm3>) | (HB Kgf/mm2) | (uO/cm<) | (%>) | (Mpa>) |

| W70/Cu30 | 13,80 | 175 | 4,1 | 42 | 790 |

| W75/Cu25 | 14,50 | 195 | 4,5 | 38 | 885 |

| W80/Cu20 | 15,15 | 220 | 5,0 | 34 | 980 |

| W85/Cu15 | 15,90 | 240 | 5,7 | 30 | 1080 |

| W90/Cu10 | 16,75 | 260 | 6,5 | 27 | 1160 |