Project Description

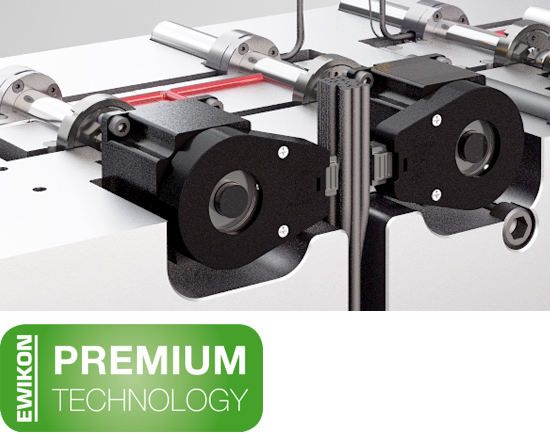

The use of EWIKON gate systems ensures excellent part surface quality with barely visible injection points, as well as significantly increased process reliability. Various designs, tip insert versions and drive options are available. This makes it possible to perfectly adapt the gate system to the specific requirements of the application and mould layout. All versions of the HPS III-S and L2X hot runner nozzles are available as gate nozzles.

More information:

Electric drive gate valve technology brochure

Advantages of using EWIKON slider technology

- High process efficiency and reliability

- Precision pin guidance and sealing technology for reduced maintenance

- Consistently high injection point quality

- Leading drive technology, various drive train versions

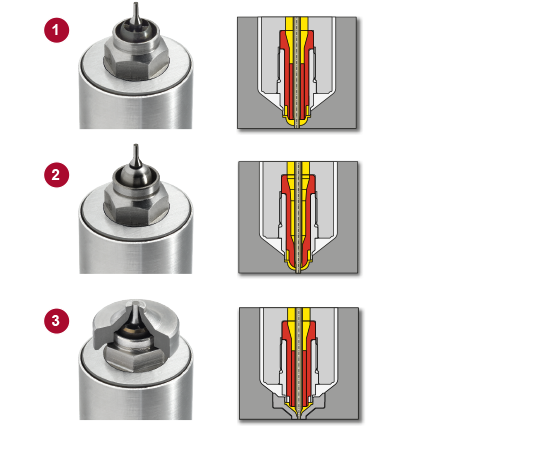

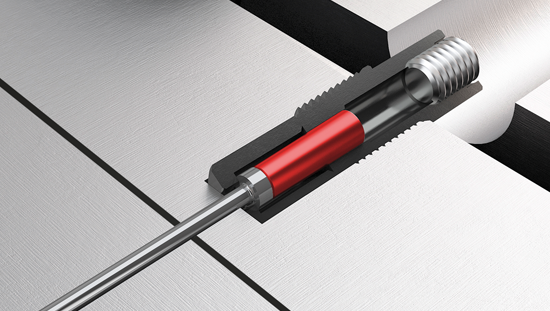

Insert versions

- Fixed valve needle guide

Needle guide at the front of the nozzle for maximum operational safety

and minimum wear of the valve needle. The valve needle is guided throughout the cycle. Ideally suited to high volume production forms in the packaging and medical industries. - Pre-centred firing pin guide

Pre-centring of the valve needle for precise immersion in the conduit. For technical resins and optical parts. - Inserts for changing tubes to increase ease of maintenance

The tube replacement inserts make it easier to maintain a tube area that is particularly susceptible to wear. The inserts are made of wear-resistant material. They contain the already machined inner contour of the conductor and are installed directly in the socket insert. In the event of wear of the conductor, the conductor insert can be easily replaced without having to machine a new socket insert.

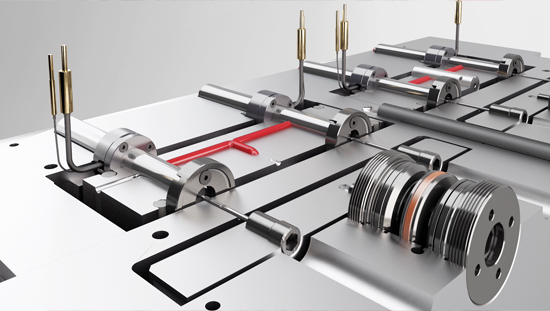

Drive versions

Single drive system with piston in clamping plate

- Standard compact solution.

- Hydraulic or pneumatic actuation.

Single drive system on distributor (coupled)

- Simplified mould layout, with no need to drill holes for power cables.

- Pneumatic actuation.

Single drive system on distributor (bolted on)

- Hydraulic or pneumatic actuation.

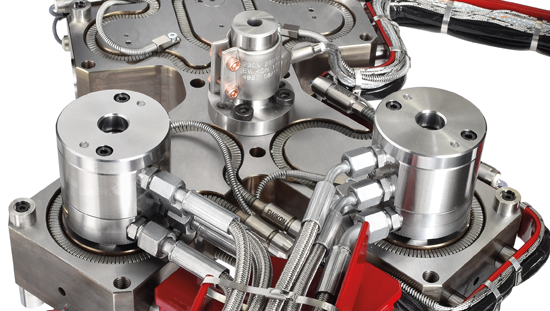

Actuation of the valve needle by electric stepper motors

- Precise positioning of the valve needle.

- No emissions. Ideally suited for clean rooms in the medical industry.

- Individual setting of all process parameters using the EDC-PRO controller.

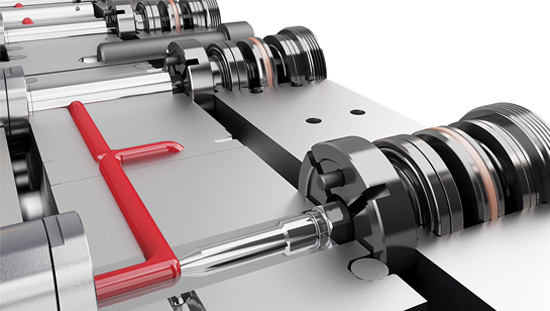

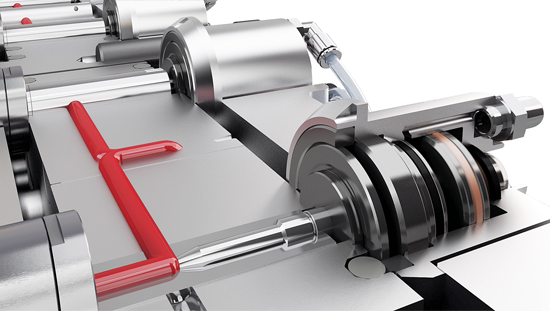

Simultaneous actuation of the valve needles thanks to synchronisation plate systems

- All the valve needles are fixed in a synchronising plate to ensure their simultaneous operation.

- Actuation by pistons in the clamping plate or pull and rail mechanism.

Option: Overload protection device

- Prevents damage to the valve needle, e.g. when the single tube is blocked by impurities in the plastic.

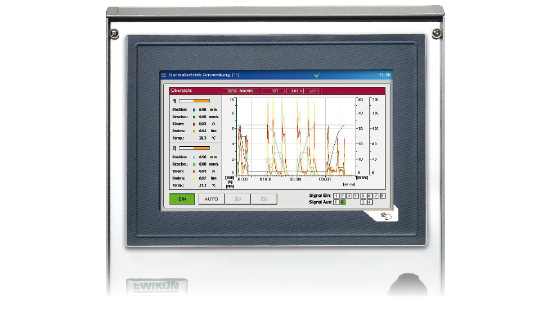

Gate system controllers

EDC-PRO touchscreen controller for linear stepper motors

- Convenient and easy to learn touchscreen operation.

- Individual setting of all relevant process parameters for up to 32 linear stepper motors.

- Sequential injection function.

- Simple production of complex valve needle movement profiles with the function of setting up to 6 valve needle positions in one moulding cycle.

- Remote access via tablet and VNC browser.

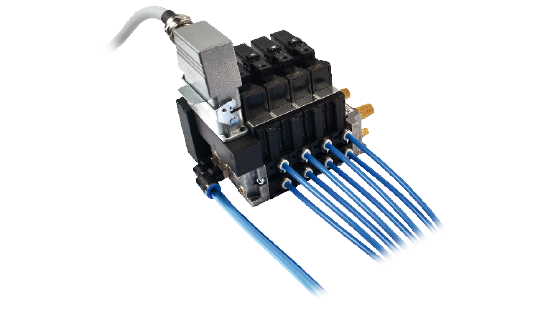

SDC-PRO touch-screen controller for linear actuators

- Precision control of linear actuators in synchronisation plate systems.

- Constant monitoring of the valve needle position.

- Individual adaptation to different applications.

- Remote access via tablet and VNC browser.

VDC controller for sequential injection with touch screen

- Precise control of the valve needle position during sequential injection.

- Operation of up to 12 drive units simultaneously.

- Available for hydraulically or pneumatically operated systems.