Project Description

Our high degree of innovation and goal-oriented research and development enable us to create a range of unique solutions to meet specific customer requirements - from systems with an exceptionally high number of outlets to particularly efficient solutions for stacked and tandem moulds.

More information:

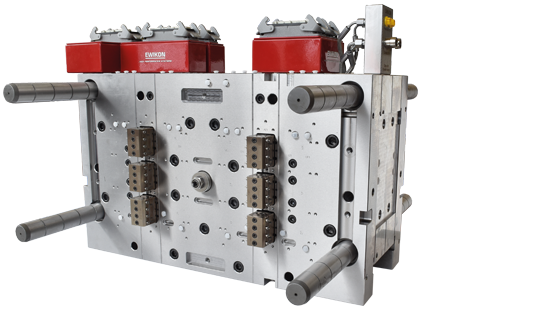

Micro distributor technology for multi-cavity moulds

For the reliable processing of polyolefins in very compact and stable multi-cavity moulds. Target industries are in particular the medical and packaging industry, where efficient large-scale production of moulded parts with low injection weights is required.

- Standardised multi-slot mould design with up to 192 slots

- Significantly reduced control effort. Only one control zone per micro distributor

- Very compact and stable mould construction

- High ease of maintenance

High-performance hot runner system L2X-Micro

For micro-injection moulding of technical resin parts with weights starting from 0.05 g on small injection moulding machines.

- Tip inserts with efficient direct heating and separate temperature control for reliable processing of technical resins.

- Hassle-free processing of heat-sensitive materials.

- Designed for use on BOY®-, WITTMANN BATTENFELD- or Babyplast® machines.

- L2X connection technology for precise positioning of the connecting cables.

Slider system for short distances between sockets

A new method of direct injection from the side with small cavity distances or injection in confined spaces using the HPS III-MH nozzle body for side injection.

- The minimum distance between the sockets is only 6 mm. It is ideally suited to multi-point pouring for medical mouldings or overmoulding in the electronics industry.

- Possibility of positioning filler points on horizontal surfaces close to vertical walls.

- Lateral plastic feed. The hose is positioned in the ejection direction of the moulded part (0°).

Stacking and tandem moulds

EWIKON offers hot runner solutions for stacked and tandem moulds in every possible configuration according to customer specifications. The transfer of plastic from the machine nozzle to the manifold system in the mould parting line is usually carried out using gate technology and is leak-free.