Project Description

Our hot runner technology specialists support every stage of a mould project, from defining the application specifications, selecting and designing the right hot runner solution, through to commissioning and after-sales support.

Our hot runner technology specialists support every stage of a mould project, from defining the application specifications, selecting and designing the right hot runner solution, through to commissioning and after-sales support.

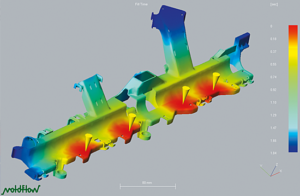

Plastic flow analyses

For optimised filling of moulded parts, taking into account flow profiles, flow lines, bubble formation and pressure requirements. Determination of injection points and calculation of system equilibrium.

Rheological design of the hot runner system

Calculation of pressure drop, shear rate and residence time.

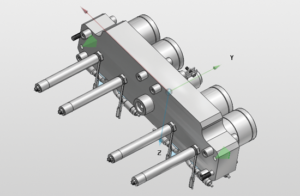

Technical support

Technical centre for pre-production testing of customer moulds, material trials using EWIKON test moulds, support for system installation and mould commissioning, as well as troubleshooting and maintenance work.

Technical centre for pre-production testing of customer moulds, material trials using EWIKON test moulds, support for system installation and mould commissioning, as well as troubleshooting and maintenance work.

Machines:

- Hot runner section: 4 injection moulding machines (500 to 1600 Mpa)

- Cold channel section: 1 injection moulding machine for LSR processing (1000 Mpa)

Library of 3D CAD mouldings

Direct interfaces to most CAD systems.