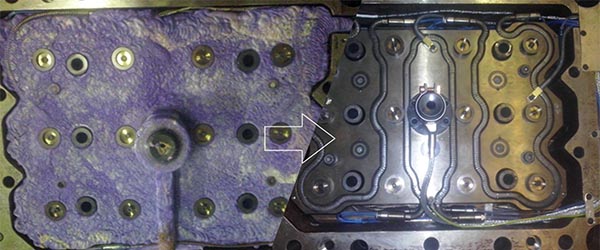

Flooded manifold? A clogged CG system? Cleaning extrusion heads takes hours and doesn't have the desired effect? We will do it for you!

KONEK PSN offers the KONEKRENEW service, which is unique on the plastics processing market, consisting in comprehensive cleaning of hot runner systems, manifolds, injection moulds, injection moulding machine components and extrusion heads and components. The proprietary method we present to you is the result of more than 20 years of experience in the tool industry and cooperation with suppliers of the highest quality components and solutions.

KONEKRENEW is a patented and innovative technological process arranged in a coherent whole so that mould downtime is kept to a minimum. We offer the fastest hot runner system cleaning on the market, together with diagnosis of the causes of plastic leakage, which prevents further production stops in the future. The service guarantees a rapid return to production without streaks or inclusions on moulded parts, while also facilitating colour changes.

For more details on the innovative KONEKRENEW service, please contact Marcin Leszczyński, Hot Channel Systems Specialist - tel. 507 029 173, e-mail address: leszczynski@konek.com.pl

KONEK_RENEW_presentation_v01