Project Description

Special requirements:

- High quality injection point and surface

- Mass production

- Short cycle times

- High repeatability

- Multi-socket systems

- Side inlet

- Compact forms

- Frequent colour changes

- IML technology

- Multi-component mouldings

EWIKON solutions:

Closure secured against opening

| Material: | PP |

| Mass of moulding: | 3.9 g |

| Hot-channel system: | Gate valve. Slim nozzles with graduated flow channel diameter to minimise pressure loss |

| Sockets: | 32 |

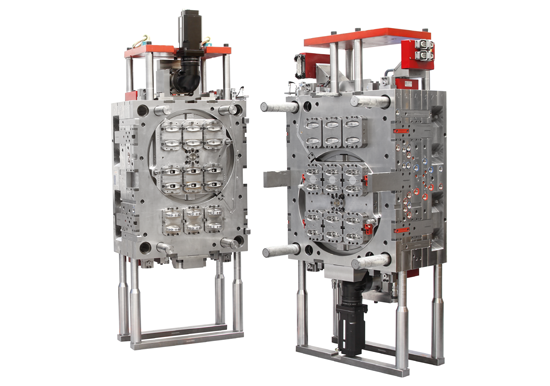

Disinfection gel container

| Material: | PP |

| Mass of moulding: | 3 g (cover) 5 g (container) |

| Form: | 3-component mould, injection with in-mould assembly + overmoulding with two rotary index plates. Production of individual moulded parts and joining by overmoulding in a single moulding cycle. |

| Hot-channel system: | Cover: Slider, slimline nozzles Overtaking: Direct filler from the side. Radial nozzles Container: Slider |

| Sockets: | 6+6+6 |

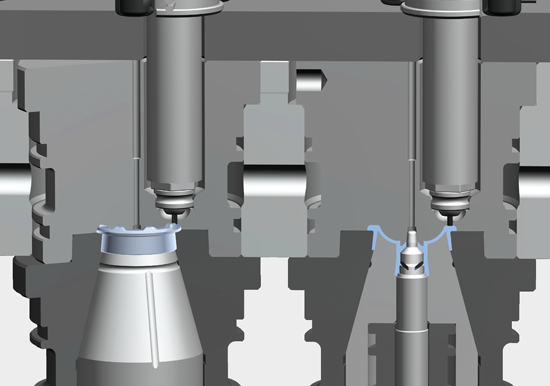

Spray nozzle for atomiser

| Material: | HDPE |

| Mass of moulding: | 1.1 g |

| Hot-channel system: | Slider. Special system with side feed for injection in confined spaces |

| Sockets: | 32 |

Pump mechanism valve

| Material: | EVA |

| Mass of moulding: | 0.35 g |

| Hot-channel system: | A bolt of slender souls |

| Sockets: | 32 |

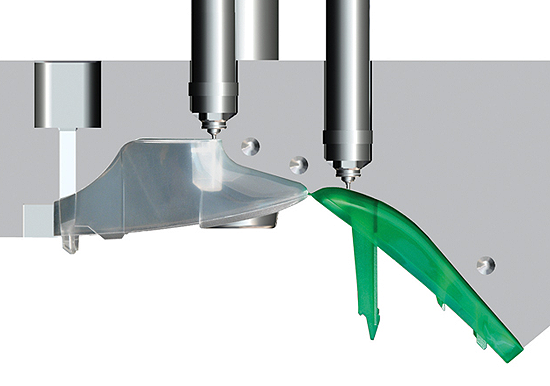

Two-piece atomiser body

| Material: | PP |

| Mass of moulding: | 5.2 g |

| Form: | 2-component mould |

| Hot-channel system: | Slender nozzle shutter |

| Sockets: | 24 |