Project Description

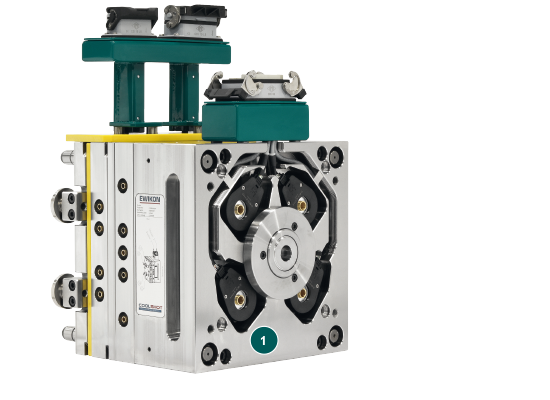

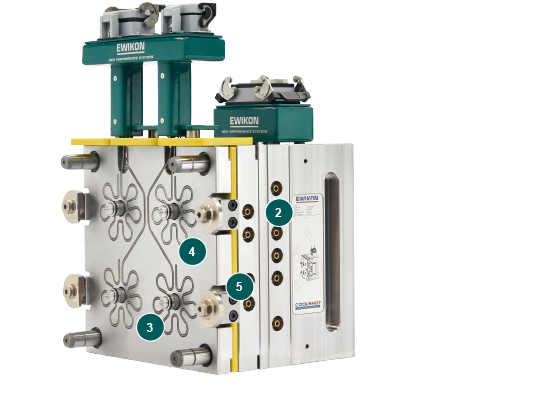

The EWIKON COOLSHOT cold runner system allows the reliable processing of all types of LSR. The innovative proven technology guarantees perfect cavity filling, homogeneous cross-linking thanks to even heating and shortened cycle times. The system is delivered as complete ready-to-install cold half.

More information:

The new benchmark for LSR processing

- Valve gate technology with electric linear step motors

Leading technology from the hot runner sector. Valve pin positioning with high precision. Minimised time expenditure for system setup and readjustments during production. - Easy-to-maintain balanced manifold technology

Balanced flow channels and streamlined flow channel layout for quick colour changes. The manifold package can be easily disassembled and opened for cleaning. - Optimised cycle times and perfect gating points thanks to advanced nozzle technology

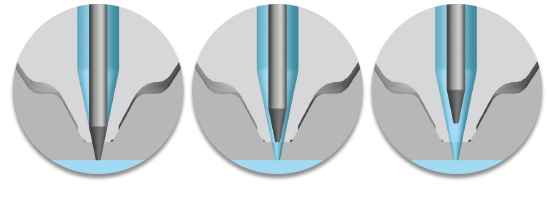

An excellent thermal separation is achieved by using different tip designs for the water cooled cold runner nozzles. This allows optimised cycle times for various types of LSR. - OPTION: Homogeneous heating of the cavity plate

Heated separator plate with powerful coil heaters and separate temperature control for each cavity. Considerably more even temperature profile when compared with cartridge heaters. - OPTION: Quick clamping device for deinstallation of the cavity plate

After the end of production or in case of a temporary interruption the hot cavity plate can be easily separated from the cold runner nozzles. A cross-linking of the LSR in the cold runner is prevented.

Perfect fine-balancing of the cavity filling

Conical valve pins combined with high-performance electric drive valve gate technology allow a precise fill control of each single cavity as well as a reliable sealing of the gate.