Project Description

EWIKON hot runner nozzles are available with a range of flow channel diameters, nozzle lengths and filler options, offering mould designers the ultimate in flexibility.

More information:

Download area of the main directory

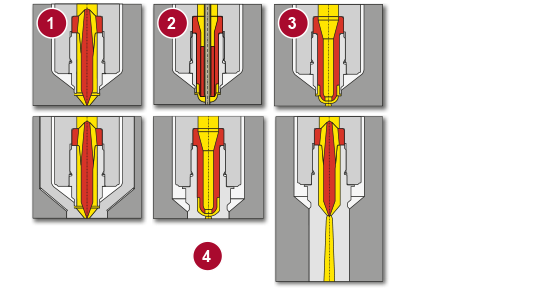

EWIKON nozzle technology - temperature stable, durable and easy to maintain

- Process reliability through direct heating

Spiral heaters and thermocouples directly integrated into precision cut-outs in the pressure tube for the plastic. Very stable heating with minimal losses translating into an even heat profile over the entire length of the nozzle. Even heating of all nozzles guarantees high process reliability and excellent system balance. - Hardened pressure tubing

Designed for a maximum plastic pressure of 2000 bar. Wear-resistant threads for effortless repeatable removal of the tip insert. - Easy maintenance and replacement

Front-mounted for easy access and nozzle replacement when the socket plate is removed. Replaceable tip, heater and thermocouple inserts. - Stainless steel protection tube

Protects the heater from damage. - Rapid colour changes

Seal the plastic directly on the filler. Only a minimal amount of plastic needs to be replaced.

Infusion options

The various sprue options provide the ultimate flexibility in terms of the position and design of the injection point.

- Injection with a thermally conductive tip

- Injection via a gate

- Injection with open flow channel

- Various versions of filler sleeves and bolt-on filler sleeves, including oversized versions to suit any mould contours

Nozzle types

HPS III-S nozzle

- EWIKON standard nozzle for all materials and injection masses.

- Available in a variety of sizes for open filler and gate valve systems.

- A slimmer version with a slot distance of just 12 mm.

HPS III-S Ø 4.5 mm open nozzle

Slider nozzles:

Gate valve nozzle HPS III-S Ø 3 mm

HPS III-S Ø 4.5 mm gate valve nozzle

HPS III-S Ø 6 mm gate valve nozzle

Gate valve nozzle HPS III-S Ø 9 mm

Single nozzle HPS III-SXE

- Single nozzle for reliable processing of all materials, including high-temperature thermoplastics.

- Two separate heaters guarantee the most uniform heat profile.

- Available in a variety of sizes for open filler systems.

Directly to the main part of the catalogue:

Single nozzle HPS III-SXE Ø 6 mm

Single nozzle HPS III-SXE Ø 9 mm

Single shutter nozzle HPS III-NVI

- Compact single gate valve nozzle with integrated drive system.

- Extremely simple installation.

Directly to the main part of the catalogue:

Single shutter nozzle HPS III-NVI Ø 6 mm

Single shutter nozzle HPS III-NVI Ø 9 mm

L2X nozzle

- Screw connector for use in L2X Drop-In systems.

- Available in various sizes for open filler and gate valve systems.

Directly to the main part of the catalogue:

Open jets:

Slider nozzles:

Multiple nozzle HPS III-MV

- For vertical multiple overmoulding.

- It is possible to overmould small parts simultaneously with small distances between cavities. Multi-point overmoulding of individual parts is also available.

Nozzle for filling system on the side HPS III-MH100

- ⦁ For direct filling system on the side.

- ⦁ Available in linear (MHL100) or radial (MHR100) versions.

- ⦁ Maximum injection mass of 10 g per hose.

Directly to the main part of the catalogue:

Nozzle for filling system on the side HPS III-MH200

- For a direct filling system on the side.

- Available in linear (MHL200) or radial (MHR200) versions.

- Maximum injection weight 40 g per hose.

Directly to the main part of the catalogue:

Nozzle for filling system on the side HPS III-MH111

- For a direct filling system on the side.

- A particularly slim version for pipette production.

- For use with a nozzle-adapter.

- Maximum injection weight of 10 g per hose.

Directly to the main part of the catalogue:

Nozzle for the side filling system HPS III-MH112/122

- For direct side filler system in moulds with a small number of slots.

- For use with a nozzle-adapter (MH112) or directly under the distributor (MH122).

- Maximum injection weight of 10 g per hose.

Directly to the main part of the catalogue: