Project Description

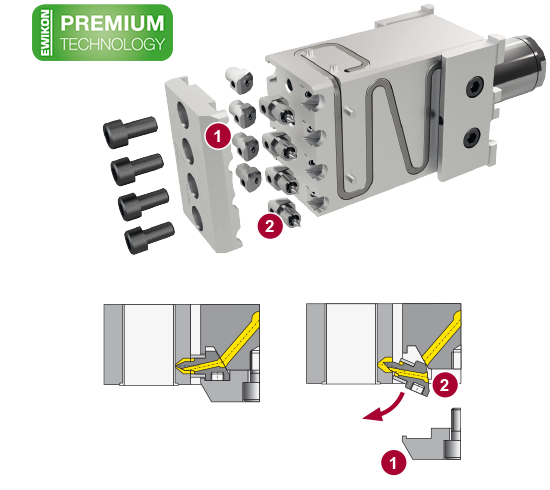

With the HPS III-MH multi-end concept, EWIKON offers the most advanced and easy-to-maintain solution for a direct side filler system. The variety of nozzle versions, sizes and filler options allows for ideal adaptation to different mould layouts and facilitates the design of compact multi-cavity moulds for the medical, packaging or technical parts industries.

More information:

Advantages of using EWIKON lateral filling system systems

- Outstanding injection point quality due to direct injection on the surface of the moulded part

- Very even heat profile

- Reduced mould costs

- Unparalleled ease of maintenance, minimised downtime

- Reduced dwell time and pressure loss

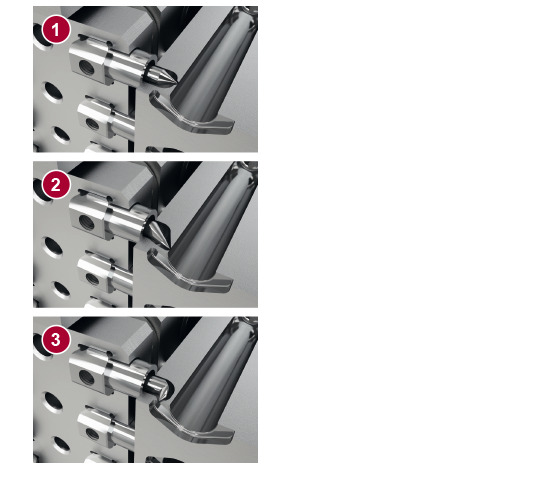

Easy exchange of the tip insert

Innovative tip replacement technology makes the HPS III-MH nozzle the most low-maintenance solution for direct side pouring. The tip inserts are placed from the mould parting line at the final assembly stage after the nozzle body has been installed and can be replaced just as easily for maintenance without the need to disassemble the mould.

- The terminal cover must be removed.

- Remove the tip insert from the mould insert and reinsert.

Gating options

- 90° gating

- 60° gating

Advantage: The gating point can be positioned closer to the location of the inner core. Thus, a core deflection caused by the melt pressure can be avoided when moulding slim, thin-walled tubular parts. - 0° gating

Advantage: The gating point can be placed in direct proximity to the part's vertical contours, for example on flanges.

Nozzle types

HPS III-MH100 nozzle for side gating

- For direct side gating.

- Available as linear (MHL100) or radial (MHR100) version

- Maximum shot weight 10 g per gate.

Go directly to main catalogue chapter:

HPS III-MH200 nozzle for side gating

- For direct side gating.

- Available as linear (MHL200) or radial (MHR200) version.

- Maximum shot weight 40 g per gate.

Go directly to main catalogue chapter:

HPS III-MH111 nozzle for side gating

- For direct side gating.

- Particularly slim version for the production of pipettes.

- Use with adapter nozzle.

- Maximum shot weight 10 g per gate.

Go directly to main catalogue chapter:

HPS III-MH112/122 nozzle for side gating

- For direct side gating in moulds with a low number of cavities.

- Use with adapter nozzle (MH112) or directly under the manifold (MH122).

- Maximum shot weight 10 g per gate.

Go directly to main catalogue chapter: